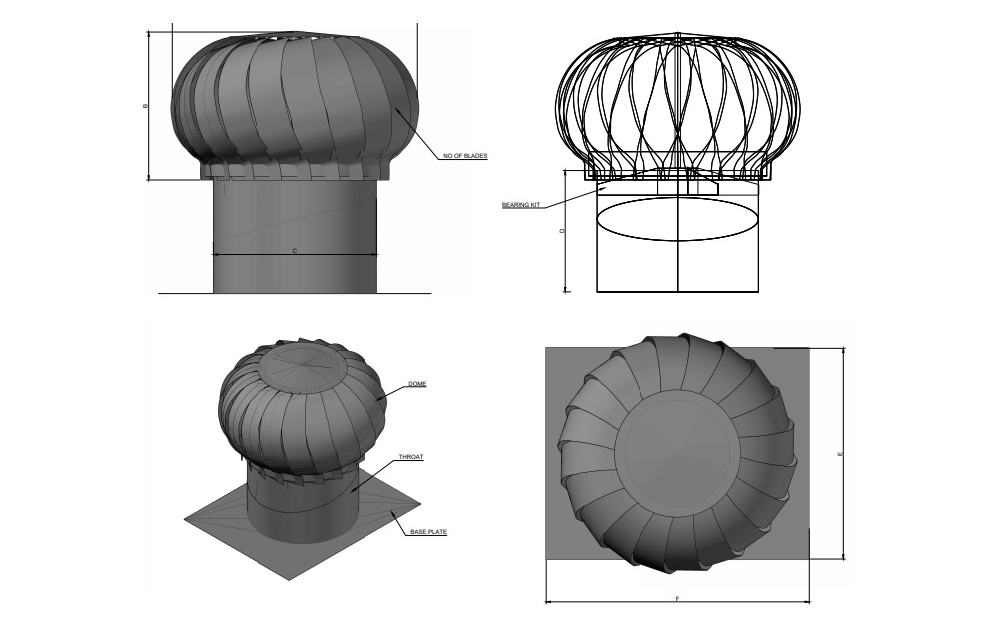

Effective ventilation can increase comfort, productivity and energy efficiency at a work place or other commercial buildings. A well designed ventilation system can reduce heat, condensation and exhaust pollutants. We have a range of products to suit commercial, industrial and residential premises.

All are products are manufactured as per the industry set standards, these ventilators are commonly used for exhausting dust and fumes out of various industrial establishments and households. These ventilators can be customized as per the specifications provided by the customers.

Owing to the optimum performance, unique pattern and minimum maintenance, our ventilators are highly demanded in the various ventilation operations. We have a team of quality controllers that monitor entire manufacturing processes to ensure a defect free range.